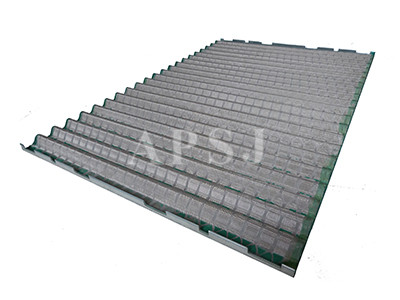

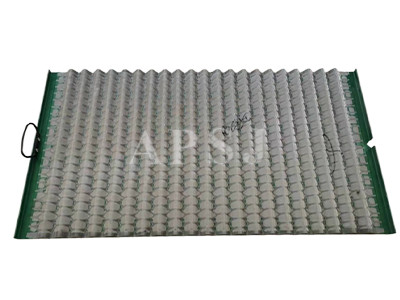

Corrugated Screen

Corrugated screen is named by his special corrugated form.Main feature as follows:

These products screen panels are constructed with two or three 304 or 316 stainless steel wire cloth layers, after compounded and bended, with a steel backing plate combined together. The wire cloth and bottom steel backing plate combined tightly, increase the filtering area 120% to 150% more than hookstrip flat screen, get an better effective.

Different layers with different density.To arrange these layers reasonably and exactly, the screening effect will become more and better. Screen with different mesh counts with suitable opening sizes of the backing plate. Doing so, our products will obtain the largest effective area under the condition of enough strength.

The bottom layer with low mesh counts has coarse wire and can be tight bonded to the backing to make up one block. So the strength of whole screen mesh get up and the useful life is increased.

Advantages

- Increased Shaker Capacity.

- Makes Fine Separations.

- Fits Existing Shakers.

- Screen Finer Faster.

- Drier Cuttings.

Specification

- Material: SS304/SS316L

- Body Material: Stainless steel plate

- Construction Type: Wave Type

- Package: 2 pcs per carton, packed in per wooden case.

| Modle | Brand&Model for shaker | Mesh Range | Dimension (Length x Width) |

Weight |

|---|---|---|---|---|

| SJZ-5 | Derriok FLC2000 Corrugated | 20—325 | 1053×697mm | 6.0KGS |

| SJZ-6 | Derriok FLC500 Series Corrugated | 20—325 | 1050×697mm | 7.8KGS |

| SJZ-7 | Derriok FLC313M Corrugated | 20—325 | 1165×700mm | 6.5KGS |